HOD's Desk

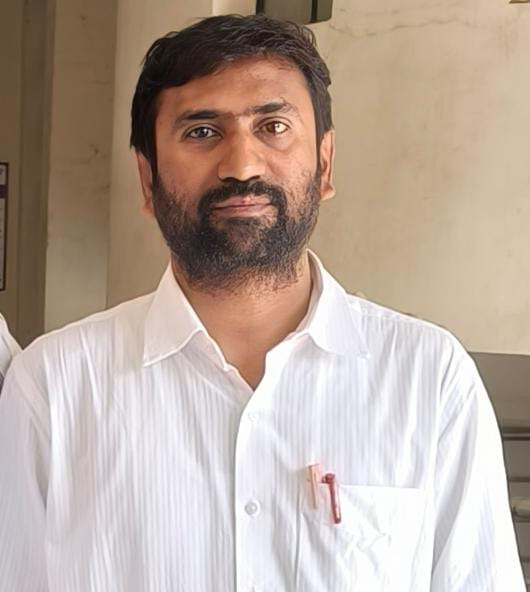

Name:

Date of Appointment:

Qualification:

Experience:

Laboratory

Plastic Testing Laboratory

Computer Laboratory

Plastic Processing Laboratory I

Plastic Processing Laboratory II

Polymer Chemistry Laboratory

| SR.NO. | Name of Laboratory | Area of Lab in Sq. m. |

| 01 | Plastic Testing Laboratory | 153 |

| 02 | Computer Laboratory | 102 |

| 03 | Plastic Processing Laboratory I | 153 |

| 04 | Plastic Processing Laboratory II | 102 |

| 05 | Polymer Chemistry Lab | 100.38 |

Study Material

Profile

-

Vision

To develop a centre for excellence in the field of Plastic Engineering for the development of need based manpower for business and industry. The department shall have training and development activities in collaboration with industry to address the emerging technology domain in the field of Plastic Engineering.

-

Mission

Department of Plastic Engineering is committed

M1. To develop employable Diploma Plastic Technicians.

M2. To create problem based learning environment for achieving academic excellence.

M3. M3. To inculcate ethical values, entrepreneurial, environmental concern and life learning skills for sustainable development of plastics and allied industries.

M4. To provide quality learning systems through development of academic processes, projects, consultancy and industry collaboration. -

Programme Educational Objectives(PEO's)

To provide the Polymer engineering technicians for meeting the current and future demands of technical manpower in plastics industry/self-employment.

To build the fundamental knowledge in mathematical, scientific and engineering fundamentals required to formulate, analyze and solve plastic engineering and related problems.

To enable plastic engineering diploma technicians to undertake design, development, production, managerial and entrepreneurial activities in the fields of plastics engineering.

To inculcate ethical practices, leadership skills, innovation, integrity, life-long learning skills and sensitivity to the needs of the society.

-

Programme Specific Outcomes(PSOs)

Synthesize, characterize and select the polymer materials.

Manufacture plastics products using suitable processing technique and suggest appropriate recycling method.

Assess the quality of plastics products and design mould.

-

Strength

100 % placement to students

Highly qualified & experience faculties

State of art infrastructure and laboratories

Good interaction with industries

All faculties are Post-Graduate -

Programme Outcomes(POs)

On successful completion Diploma pass out student's will be able to

Basic and Discipline specific knowledge: Apply knowledge of basic mathematics, science and engineering fundamentals and engineering specialization to solve the engineering problems.

Problem analysis: Identify and analyses well-defined engineering problems using codified standard methods.

Design/ development of solutions: Design solutions for well-defined technical problems and assist with the design of systems components or processes to meet specified needs.

Engineering Tools, Experimentation and Testing: Apply modern engineering tools and appropriate technique to conduct standard tests and measurements.

Engineering practices for society, sustainability and environment: Apply appropriate technology in context of society , sustainability, environment and ethical practices.

Project Management: Use engineering management principles individually, as a team member or a leader to manage projects and effectively communicate about well-defined engineering activities.

Life-long learning: Ability to analyses individual needs and engage in updating in the context of technological changes.

-

Staff Achievements

Name of Faculty No. of Paper Published/Conference Attended No. of Training attended palsodkar 5 5 MR. NITIN N. THAKARE 5 10 Dr. Shamli Ambadas Chopde 5 25 Smt. Surabhi P. Choudhary 3 18 Mr. Mangesh Shamrao Deshmukh 2 19 -

Industrial Visits

Name of Industry or Location Date Class No. of Students EPC MAHENDRA AND UKAY INUSTRIES, AMABAD NASHIK 2023-10-12 3 60 BAYMER ELASTOMER PVT LTD NASHIK 2022-04-20 2 55 -

Memorandum of Understanding (MOU)

2

-

Result Analysis

Entry No. of Students I Year(pass) II Year(pass) III Year(pass) SUMMER-2024 79 24 80 77 WINTER-2023 121 14 33 77 Academic Performance of Final Year

Entry I Year(pass) II Year(pass) III Year(pass) 2024 77 71 75 -

Program Wise Committee (PWC)

Sr.No. Name PWC Designation 01 Dr. A. D. Palsodkar

Head of Plastic Engineering DepartmentChairman 02 Mr. Manoj Jaiswal

Industry ExpertMember 03 Mr. Rahul S Patil

Industry ExpertMember 04 Mr. Abhijeet Chandra

Industrial ExpertMember 05 Shri. N. G. Deshmukh

Programme Expert From Neighboring InstituteMember 06 Shri.N. N. Thakare

Senior Lecturer from ProgrammeMember 07 Smt. S. P. Chaudhari

Senior Lecturer from ProgrammeCo-opted Member 08 Mr. A. D. Joshi

MSBTE RepresentativeMember 09 Shri. S. P. Dikshit

Incharge Curriculum Development CellMember Secretary

Timetable - newsletter

| Name | Profile | Designation | Qualification | Experience |

| A palsodkar | Head Plastic Engineering | PHD | 23 | |

| Mr. Nitin Nanasaheb Thakare | Lecturer (Selection Grade) | Ph. D. Pursuing | 21 | |

| Smt. Surabhi P. Choudhary | LECTURER | M. Tech Chemical Technology | 15 | |

| Dr. Shamli Ambadas Chopde | LECTURER | Phd in Chemical Technology | 15 | |

| Mr. Mangesh Shamrao Deshmukh | LECTURER | M E PLASTIC ENGG | 15 |

Achievements

-

Academic Achievements

Name of the Student Year Status -

Other Achievements

Name of the Student Name of the Competition Year Status

Future Plans